The smart Trick of What is Prototyping? - Interaction Design Foundation (IxDF) That Nobody is Talking About

Rapid Prototyping Company - LA NPDT for Beginners

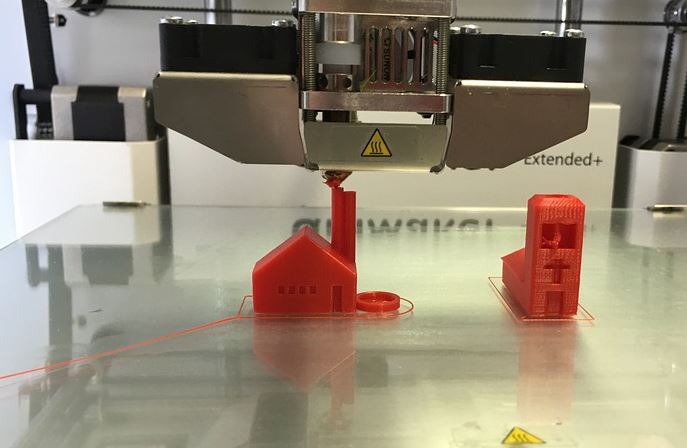

3D printed parts can be completed with secondary procedures like sanding, polishing, painting, or electroplating to reproduce any visual attribute of a last part, in addition to threaded to produce assemblies from several parts and products. Engineering prototypes require comprehensive functional and use screening to see how a part or assembly will operate when subjected to tensions and conditions of in-field use.

What Is 3D Prototyping? – Simply Explained - All3DP

Rapid prototyping enables engineers to produce small-batch runs, one-off customized services, and sub-assemblies for engineering, design, and item recognition (EVT, DVT, PVT) builds to evaluate manufacturability. 3D printing makes it simpler to check tolerances with the real manufacturing process in mind, and to conduct comprehensive internal and field screening prior to moving into mass production.

Prototypes: what are they and how they make your product better?

Excitement About The 6 Types of Prototyping Every New Product Must Do

The technology also provides an efficient service for creating custom test jigs and fixtures to streamline practical testing and certification by collecting constant data. With 3D printing, design doesn't have to end when production starts. Fast prototyping tools allow designers and engineers to constantly enhance items, and react rapidly and successfully to concerns on the line with jigs and fixtures that improve assembly or QA procedures.

Additive Manufacturing, Rapid prototyping has actually essentially become associated with additive manufacturing and 3D printing. There are several 3D printing processes available, with the ones most commonly used for rapid prototyping being merged deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS).FDM 3D printing, also referred to as merged filament fabrication (FFF), is a 3D printing technique that develops parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the develop location.

The smart Trick of Is It Worth Investing in Plastic Product Prototyping? - Global That Nobody is Discussing

Professional FDM printers are, nevertheless, also popular with both designers and engineers. This Is Cool has the lowest resolution and precision when compared to other plastic 3D printing procedures and is not the best choice for printing complicated styles or parts with intricate features. Higher-quality surfaces may be gotten through chemical and mechanical polishing procedures.

FDM deals with a variety of standard thermoplastics, such as ABS, PLA, and their various blends, while more innovative FDM printers likewise provide a broader variety of engineering thermoplastics or even composites. For fast prototyping, FDM printers are particularly beneficial for producing simple parts, such as parts that might usually be machined.SLA 3D printers utilize a laser to treat liquid resin into solidified plastic in a process called photopolymerization. With Draft Resin, SLA 3D printing.